Bang Energy - High-speed Beverage Line

Pembroke Pines, FL

High-Speed Beverage Facility – Project Engineering

Served as project engineering lead for the development and launch of a high-speed beverage production line, capable of filling 750 PET bottles per minute. This project spanned from the earliest planning stages through start-up and commissioning and included coordination with both a design-build firm for the complete renovation of an 80,000 sq. ft. facility and an integration company for seamless production line implementation.

Our role was to ensure that every phase of this large-scale project aligned with the client’s goals for speed, efficiency, and long-term operability. We acted as the client’s advocate, bridging the gap between construction, equipment suppliers, and integrators to deliver a turnkey solution that met technical, regulatory, and operational standards.

Our scope included:

Facility Renovation & Utilities

Coordinated with the design-build firm to manage the full renovation of the existing 80,000 sq. ft. building.

Oversaw utility expansions and installations, including propane, wastewater, compressed air, steam generation, and incoming water processing.

Production Line Integration

Partnered with an integration company to support start-up, commissioning, and system validation of the entire high-speed line.

Oversaw PLC programming, backup battery systems, and controls integration to ensure reliability and uptime.

Packaging & End-of-Line Automation

Guided equipment selection and installation, including bottle unscramblers, air conveyors, filling and capping systems, and inspection equipment for fill levels and closures.

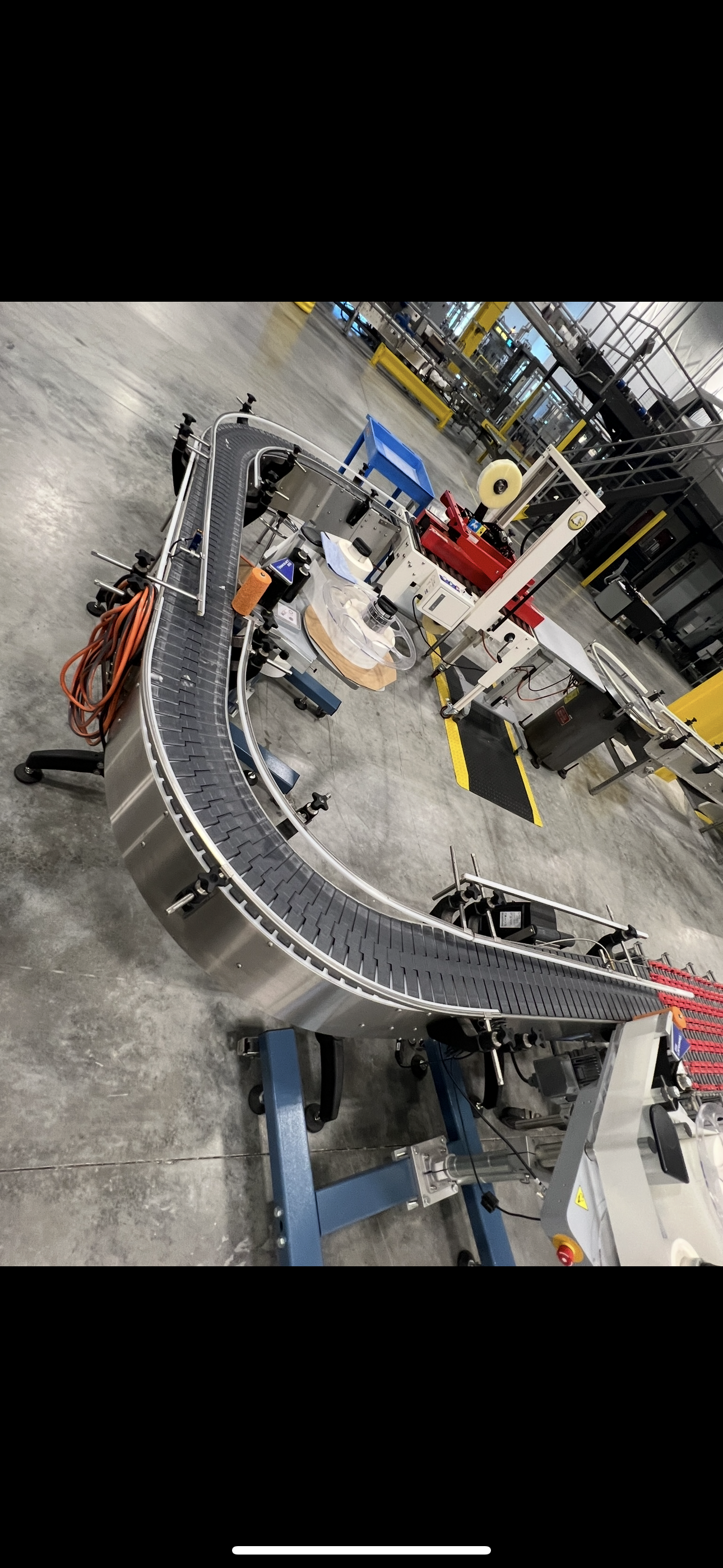

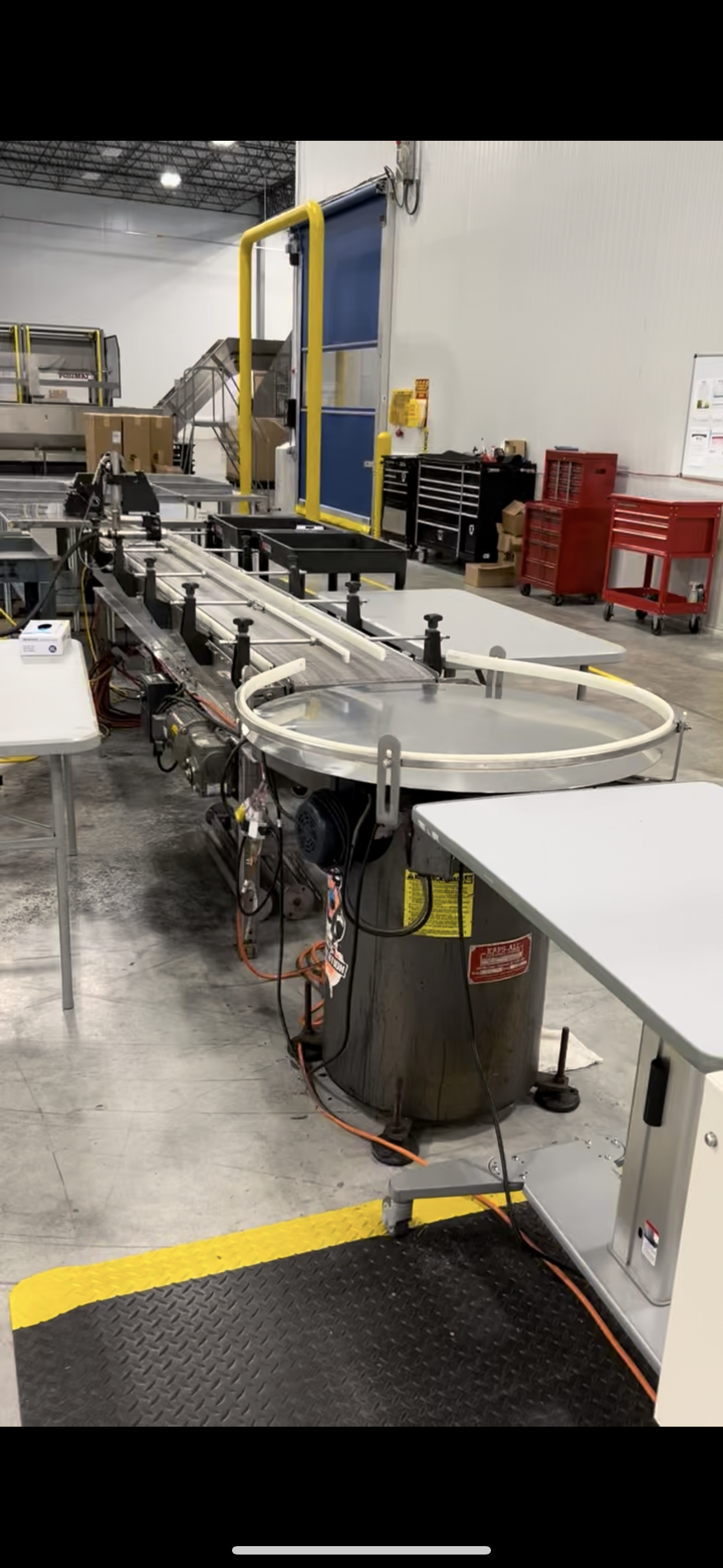

Coordinated bottle warming, automated conveyor systems, sleeving, case erecting, casing, and robotic systems for case packing, palletizing, and stretch wrapping.

Operational Systems & Continuous Improvement

Implemented maintenance strategies and continuous improvement systems to optimize uptime, reduce waste, and ensure long-term efficiency.

By managing both the technical complexity of utility and process systems and the precision required for high-speed packaging and automation, INSOCO delivered a fully integrated beverage facility ready for large-scale production. The result was not only a facility renovation, but a world-class manufacturing line designed for speed, reliability, and growth.